A McKinsey Global Institute report in 2020 suggested that supply chains will face disruptions lasting a month or longer every four years. With this in mind it is perhaps worth starting with the definition – a supply chain is a set of three or more organisations linked directly by one or more of the upstream or downstream flows of products, services, finances, and information from a source to a customer. Supply chain risk or resilience management involves proactively managing the two-way movement and coordination of goods, services, information, and funds from raw material through to the end-user. It also involves ensuring the supply chain complies with relevant regulations and does not damage your reputation, baring in mind there is an increasing expectation that you take responsibility for the multi-tiers within your supply chain.

The increased globalisation and outsourcing of elements of production or service provision have inevitably introduced increased complexity to supply chains. This greater complexity, combined with commodity, financial, pandemic, climate, and political uncertainty has elevated everyone’s awareness of risk. Supply chain risk management has become an increasingly important process in driving overall organisational performance. It is also important to realise that risk in a supply chain can equate to cost, for example a part not arriving and a production line stopping with the consequent costs involved.

COVID-19 has been a timely reminder of the fact that most organisations depend on having a resilient supply chain to be able to serve their customers, in fact as has been shown on many occasions they now compete based on their supply chains. The values at risk within these supply chains has also grown, driven by the increasing move to specialisation within production and the leaning of these global supply chains. This can mean that the failure of just one supply chain node can have incredibly significant impacts on an organisation’s financial performance.

It is therefore critical that organisations invest the appropriate amount of resources to ensure they have the right level of supply chain resilience. This focus on supply chain resilience needs to be driven from the top of the organisation and recognise the significant overlap with the need for sustainability performance, in terms of the joint requirement to drive supply chain transparency. This needs to ensure that the appropriate level of investment is available and that the initiative is driven forward on a cross functional basis in accordance with an agreed overall business plan.

In preparing for the future in a post-COVID-19 world in many cases organisations will need to restructure their supply chains and in doing this it will be critical to consider risk appropriately. This is not only about pandemic risk, but the ongoing financial, geopolitical and climate risks that will be faced by these supply chains.

It is important that these supply chain risk management efforts are also appropriately integrated into supply chain digitalisation activities that are being progressed. As we move forward, the use of new technology and data sources offer a significant opportunity to drive forward improved supply chain resilience and sustainability in a way that improves financial performance.

Changing Risk Environment

A combination of different risk drivers such as those related to climate change and increasing geopolitical tensions which have only been heightened because of COVID-19, mean that, as many pieces of research have shown, the world is only getting to be a riskier place.

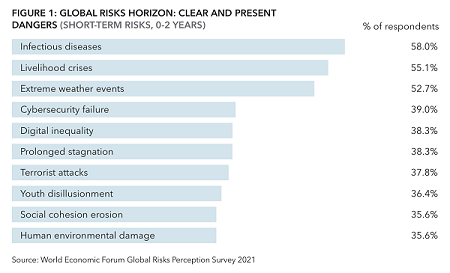

The recently published World Economic Forum (WEF) Global Risk Report 2021, shows four of the most common ‘forecast clear and present danger risks’ from the research respondents – infectious diseases, livelihood crisis, extreme weather events and cyber security failure – all have strong correlations with supply chain risk (figure 1).

Four of these top five being those of infectious diseases, climate action failure, biodiversity loss and natural resource crises. The fifth, that of weapons of mass destruction, of course could also cause supply chain challenges but at that point I think we’ll have many other things to worry about!

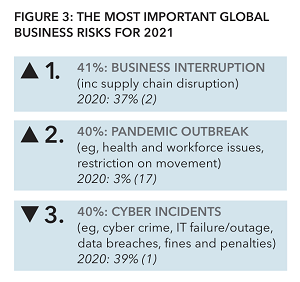

The Allianz Risk Barometer for 2021, which had 2,769 respondents, from 92 countries and 22 different industry sectors had business interruption as its number one risk and this included supply chain disruptions. In fact, all the top three risks are interlinked, demonstrating the growing vulnerabilities and uncertainty of our highly globalised and connected world, where actions in one placecan spread rapidly to have global effects (figure 3).

The pandemic shows companies need to prepare for a wider range of business interruption triggers and extreme events than previously. Building greater resilience in supply chains and business models will be critical in managing future exposures.

Supply chain risk management

We have seen on many occasions where organisations did not understand their financial exposure to a particular supplier production facility or a logistical hub and have suffered major profit and cash flow impacts. The investment community is also taking a much closer look at an organisation’s supply chain and how this is being managed from an overall business performance perspective. Larry Fink, the CEO of BlackRock – representing over $8 trillion in assets under management – wrote in his annual letter last year that sustainability is at the centre of BlackRock’s investment practices, a ‘major turning point for the world’s largest asset manager.’ Fink called on every government, company, and shareholder to confront climate change as a unique and material financial and investment risk. You cannot tackle your climate change risk without considering your supply chain which represents a large part of your footprint and exposures. This need for transparency throughout your critical supply chains is a common requirement from both a supply chain resilience and sustainability perspective.

You can make significant improvements in your business performance with relatively small investments in your supply chain resilience, particularly where you ensure that this is a top management initiative that is coordinated on a cross functional basis. For example, several of the risk data sets that you can apply once you have mapped out even just your critical Tier 1 supplies are either free or subject to a small cost. There is also a major benefit to be gained from just clarifying the responsibilities and accountabilities within your organisation in respect of supply chain risk governance and seeking to ensure your critical suppliers also have this governance in place.

It can be challenging to get your supply chain resilience programme off the ground, although COVID-19 has helped move this for many to the top of the agenda. There are three key areas it is worth focusing on initially:

- making the business case for supply chain resilience;

- obtaining executive support; and

- overcoming the silos and bringing in ‘black-box thinking’ culture.

There is nearly always a compelling business case to be made for implementing a supply chain resilience programme, the benefits that can be realised include the following:

- avoidance or mitigation of major supply chain disruption events protecting cashflow and profitability;

- understanding of low-level disruptions allowing a number of these to be eliminated over time and hence cost efficiencies to be achieved e.g., increased air freight costs being avoided by use of sea freight or short-term shutdown of production processes or services;

- staff cost savings in terms of the time taken up to deal with disruption events and monitoring potential risk events;

- avoiding potential cost variances in obtaining replacement parts or services and inventory optimisation using improved data;

- transparency derived can also help in protecting brand value and loss of customers due to supply chain reputational damage; and

- avoidance of regulatory fines.

The business case in turn is a key aspect of obtaining the required executive support to ensure the appropriate resources are put into place. For example, a technology solution can be critical to enable you to scale up for the number of risks and suppliers that you will need to monitor. The executive team can then also ensure that functional objectives are appropriately aligned to ensure overall business performance is maximised through adequate and aligned supply chain resilience performance indicators.

This alignment of objectives is important in ensuring that the functional silos such as procurement, finance, operations, sales and risk are all pulling in the same direction and providing a common message to key supplier partners. It also helps create a culture where there is appropriate transparency around the issues that are arising in the supply chain and the lessons that can be learned to avoid them happening again. This is similar to the culture present in the airline industry through its ‘black-box thinking’ approach, where any near misses are reported to encourage learning and improvement.

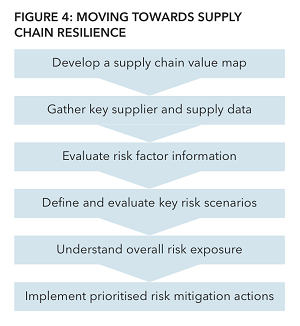

When you start to implement your improvements in supply chain resilience, one of the challenges can be to determine which of your customer product or service supply chains you should start with. From a business performance perspective this should be that product or service that contributes most to your profitability. Once you have done this, the diagram illustrates at a high level how you might move towards improvements to supply chain resilience (figure 4).

It is important when you are evaluating the risk factor information relevant to the supply chain, that you take a comprehensive approach to the supplier and supply evaluation. You should at least consider the following factors relevant to a supply and supplier:

- natural catastrophe or geopolitical risks to the supplier’s production/service site or the key logistics hubs where required to get the product to the end customer;

- suppliers’ financial solvency, cyber security, health and safety, corporate social responsibility (including appropriate labour practices), business continuity arrangements;

- suppliers’ understanding of their critical component suppliers relevant to the particular product being produced for you and the supply chain risk management practices that have been implemented;

- a news and social media search for the last 12-24 months for relevant supplier factors such as frequent changes in senior management, labour unrest etc; and

- validating that none of the subcomponents/ raw materials present risks for example, conflict minerals.

Use of technology and data

To be able to scale your supply chain resilience efforts effectively, even where you are only looking to monitor say 20 critical suppliers, then the only way to achieve the required level of risk monitoring and mitigation is to make use of technology and data. The good news is we now have technology and data available which is both user friendly and cost effective.

The key to all these technological solutions is that they provide actionable risk insights. This technology now already contains the following functionality:

- an ability to map a supply chain to provide the relevant level of transparency including the lower tiers of supply (provided they can be ascertained). This need is increasingly being required from a regulatory perspective;

- a capability to overlay near real time supply chain risk incidents relevant to the network that has been mapped;

- an ability on a global basis to understand the relative natural catastrophe, geopolitical and relevant operational risks related to a geolocation, data quality obviously varying depending on the location;

- a capability to review a supplier from a news and social media perspective (including local news and in multiple languages), in terms for example of their activities relevant to financial performance, sustainability, ethical and labour practices. Machine learning algorithms are also being applied to remove noise from the data being provided;

- an ability to look at logistical/shipping lane risks, a critical aspect of any goods/related supply chain; and

- a capability to perform ‘what if scenarios’ on critical supply chains to enable risk mitigation efforts to be improved and impacts to be understood.

Conclusion

In summary, it is imperative to optimise your financial performance so as to ensure:

- that appropriate supply chain resilience is embedded in all aspects of your supply chain management processes from supplier selection through ongoing supplier management;

- that you make use of the relevant technology and risk data that is now readily available to support these process improvements; and

- that you consider applying relevant potential risk scenarios, such as those of climate change, to your high-value supply chains as is increasingly expected by investors.

Box 1: How to benefit from supply chain resilience - examples

There are many examples of the financial benefits that can be obtained from even small investments in supply chain resilience, including in the case of the current COVID-19 pandemic.

- A technology company who had before the Japanese tsunami in 2011 already mapped out the critical suppliers that it had based in Japan and was therefore able to buy the components that it recognised were likely to be in short supply, and thus protect its financial results.

- A European company who understood at the start of the COVID-19 crisis that it had exposure to Wuhan province from its supply base so was able to shift three months inventory in advance, before lockdown, to protect its ongoing performance.

- Staff cost savings from the appropriate integration of supply chain risk processes across organisations, including the use of mapping and risk alerting solutions to reduce the frequency of increased costs due to higher logistics or material costs and the loss of sales.

- An understanding of profit concentration supply chain dependencies, such as a company that had sited both of its key component suppliers in Mexico and another company where 80% of its most profitable product line was dependent on a particular port staying open. In both cases the companies concerned over time developed further resilience by changing their geographic sourcing strategies.

- One of the basic ways of protecting your supply chain to meet customer demands is to build up inventory, but as we know this can have significant costs associated with it. The company concerned in this case through using an integrated and agile approach to supply chain resilience through targeted data use as part of an overall technology solution was able to achieve appropriate inventory optimisation and hence improve financial performance.

About the author

Nick Wildgoose is CEO at Supplien Consulting which helps organisations improve their supply chain resilience, and director at Procurement Advantage.

Related resources

More support on business

Read our articles, eBooks, reports and guides on risk management.

Risk management hubeBooks on risk